In the field of LED lighting technology, there are two main types of LED drivers: isolated and non-isolated. While both serve the same purpose of providing electricity to electronic devices, there are significant differences between them, especially in terms of design, performance, cost, and safety.

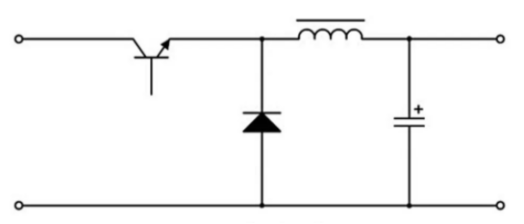

Firstly, let's explore the non-isolated LED driver, also known as the buck regulator. This type of LED driver directly converts the input voltage to the desired voltage required by the LED. It does not require a transformer, resulting in a more streamlined and cost-effective design. The absence of a transformer also means that the power supply is lighter and smaller, which is beneficial for LED fixtures that require minimal bulk.

In terms of performance, non-isolated LED drivers boast a high efficiency rate, often exceeding 90%. This is due to the absence of a transformer, which traditionally incurs significant energy losses. However, to protect against surges, non-isolated LED drivers require a surge suppression device on the input side.

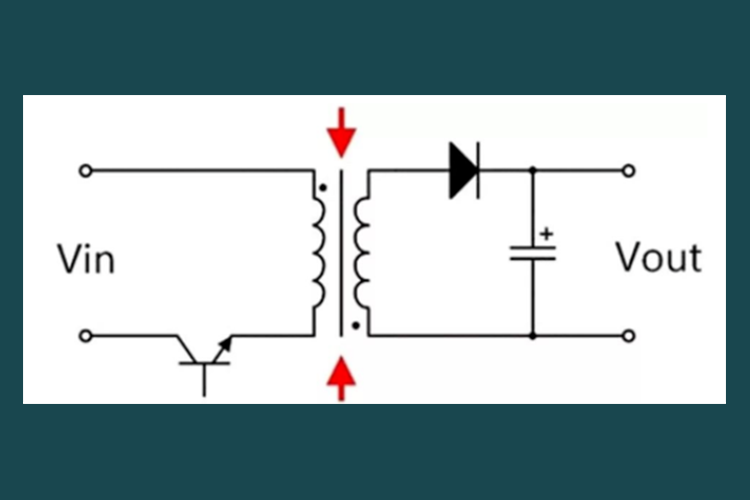

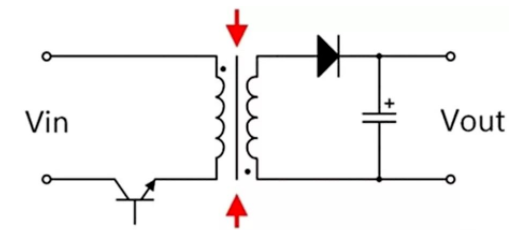

Now, let's turn our attention to the isolated LED driver. Unlike non-isolated models, isolated LED drivers feature a transformer that converts the input voltage to a higher or lower voltage. This isolation barrier ensures that even if there is a failure within the driver, it will not affect the main driver, thus enhancing safety. However, this added layer of isolation comes at the cost of increased size and weight compared to non-isolated models. Plus, isolated power supplies tend to have lower overall efficiency due to the transformer losses.

In terms of application, non-isolated LED drivers are generally used in low-voltage electronic devices where size and weight are important considerations. These include battery-powered devices, small appliances, and low-power electronics. On the other hand, isolated LED drivers are used in high-voltage or high-power applications where safety is a critical concern. These include medical equipment, industrial controls, and high-voltage power supplies.

In conclusion, both isolated and non-isolated LED drivers have their unique advantages and disadvantages. Non-isolated models offer cost-effectiveness, small size, and weight but with potential safety risks. Conversely, isolated models provide enhanced safety but at the cost of increased size and weight as well as lower efficiency. The choice between the two depends largely on specific application needs and safety considerations.